ORCA®

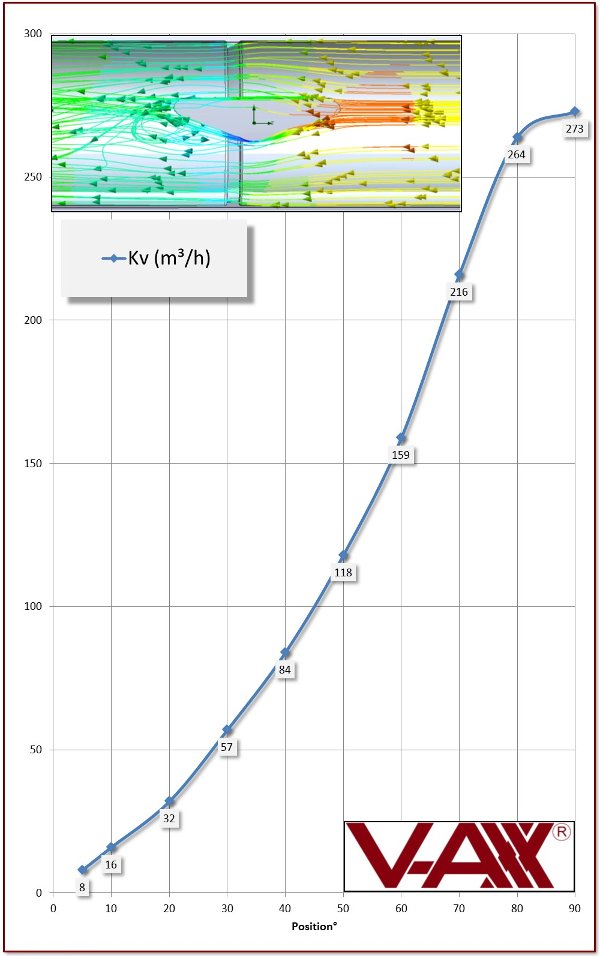

The V-AXX® valve has the highest Kv / Cv of any comparable torque-seated, butterfly valves. How important higher Kv / Cv value? In new construction, when the higher Kv / Cv of the V-AXX® is considered, the size of the valve can be reduced, minimizing the cost of the valve. But that is just the start. It's lower torque (combination of smaller valve size, but also the completely friction free sealing design) allow for a smaller, less costly automation package. Then, with the smaller valve, the piping and the associated supports are also smaller and less costly. In new construction, something once thoght insignificant, Kv / Cv values, can have a huge impact on the total costs of the investment if You are able to use for example DN 350 instead of DN 500. With regards to day to day valve replacement where the pipe size and infrastructurehave already been determined, the higher flow coefficents with the V-AXX® valve, can improve process and lower pumping costs due to the lower pressure drop across the valve.

| DN | 50 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kv Max | 39 | 125 | 273 | 443 | 693 | 1532 | 2598 | 3633 | 5427 | 7760 | 10585 | 12845 | 20408 |

| Cv Max | 45 | 145 | 316 | 512 | 801 | 1771 | 3003 | 4547 | 6274 | 8971 | 12237 | 14850 | 23593 |